What is die casting ?

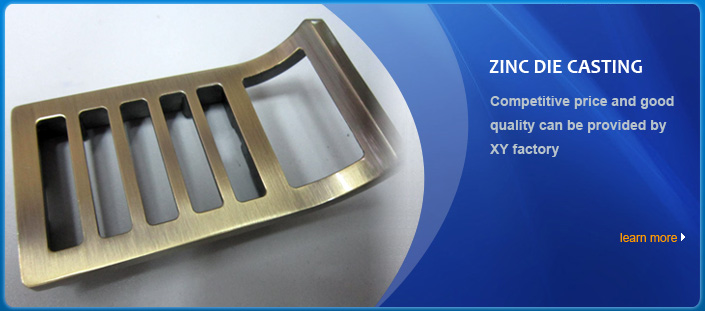

Die casting is a process in which various metals can be cast from molten states into a mold. These molds are called “dies” in many foundry environments. The die is filled with typically non-ferrous metals, such as zinc and aluminum. It is filled in a high-pressure application that ensures that the density of the die-cast material is at the desired level.

The metal is injected into a specific cavity or mold that has been created. This is then machined to create two opposing steel dies. After the cooling process is completed, the casting is then removed from the mould. It is next burred or buffed to create a product that has been manufactured to exact specifications.

How does die casting work ?

First, a steel mold capable of producing tens of thousands of castings in rapid succession must be made in at least two sections to permit removal of castings. These sections are mounted securely in a machine and are arranged so that one is stationary (fixed die half) while the other is moveable (injector die half). To begin the casting cycle, the two die halves are clamped tightly together by the die casting machine. Molten metal is injected into the die cavity where it solidifies quickly. The die halves are drawn apart and the casting is ejected. Die casting dies can be simple or complex, having moveable slides, cores, or other sections depending on the complexity of the casting.

The complete cycle of the die casting process is by far the fastest known for producing precise non-ferrous metal parts. This is in marked contrast to sand casting which requires a new sand mold for each casting. While the permanent mold process uses iron or steel molds instead of sand, it is considerably slower, and not as precise as die casting.

What products suit for die casting ?

The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small to medium sized castings, which is why die casting produces more castings than any other casting process. Die castings are characterized by a very good surface finish(by casting standards) and dimensional consistency.

Types of die

Dies are classified as: single cavity, multiple cavity, combination and unit dies.

A single cavity die requires no explanation. Multiple cavity dies have several cavities which are all identical. If a die has cavities of different shapes, it’s called a combination or family die. A combination die is used to produce several parts for an assembly. For simple parts, unit dies might be used to effect tooling and production economies. Several parts for an assembly, or for different customers, might be cast at the same time with unit dies. One or more unit dies are assembled in a common holder and connected by runners to a common opening or sprue hole. This permits simultaneous filling of all cavities.

TEL:(86-769)-86249838 FAX:(86-769)-86249978 Guangdong ICP:16129400号 网站备案/许可证号:粤ICP备16129400号